جزئیات محصول:

پرداخت:

|

| Cladding Material: | SB265 Gr.2 | Base Material: | SA105 |

|---|---|---|---|

| Size: | (14+180)*OD1800mm | Max. Size: | 28sqm |

| Production Code: | ASTM B898, ASME SB898 | Surface Treatment: | Auto Polished |

Drilled B265 Gr2 / SA105 Explosion Bonded Clad Plate Tubesheet for Heat Exchangers

Description:

| Cladding Metal: | SB265 Gr.2 | Production Code: | ASTM B898, ASME SB898 |

| Base Metal: | SA105 | Machining: | CNC Machined and Drilled |

| Size: | (14+180)*OD1800mm | Specification: | as per drawing |

Clad plates provide an economical solution for chemical processing. Explosion welding is a solid state joining process in which explosive energy is used to propel the component metal parts together to form a metallurgical bond. At the point of impact of the two components, a thin layer is stripped from both colliding surfaces and is ejected as a molten metal jet. This jet contains the surface contaminants and oxides that would otherwise prevent bonding. The two surfaces are in intimate contact under extreme pressure enabling the bond to be formed.

Table for available type of titanium clad plates:

|

Product Names: |

Titanium Clad Plate/Sheet, Titanium Clad Tube Sheet/ Tube Plate |

|||

|

Production Codes: |

ASTM B898, ASME SB898, ASTM B264, ASME SB264, ASTM B265, ASME SB265, ASTM B432, ASME SB432, DIN , BS, JIS, GB/T, ISO, etc. |

|||

|

Titanium Grades: |

ASTM/ASME B265 Gr1, Gr2, Gr.3, Gr.5, Gr7, Gr.9, Gr12 |

|||

|

Form |

Description |

Base Layer |

Base Layer Grade |

Maximum Size |

|

Clad Plate |

Titanium / Carbon Steel Clad |

Carbon steel plate and forging |

SA516 Gr.60(N),Gr.70(N),SA387 Gr.11, Gr.22, SA266, SA350, etc. |

(1.5~14)/(2~200) x W(max W 4110) x L(max L 7000) |

|

Titanium / Stainless Steel (Duplex) Clad |

Duplex, Stainless Steel & their forgings |

304L,316L, 316Ti, 321, 317L, 310S, 410S, 904L, 1805, 2205, 2507, Al6XN, 254sMo,etc. |

(1.5~14)/(2~200) x W(max W 4110) x L(max L 7000) |

|

|

Titanium / Copper (Naval Brass) Clad |

Copper, Naval Brass |

C10100, C10200, C11000, C26200, C28000, C46400, C70600, C71500, etc. |

(1.5~14)/(2~100) x W(max W 2100) x L(max L 6000) |

|

|

Titanium / Aluminum Clad |

Aluminum |

A1050, A1060, A1070, A1100, A5052, etc. |

(1.5~14)/(6~50) x W(max W 1500) x L (max L 4000) |

|

|

Titanium / Nickel Clad |

Nickel and its alloy |

N02200, Monel 400, Inconel 600, Incoloy 800, 825, C276, C22, etc |

(1.5~14)/(6~50) x W(max W 2000) x L (max L 5000) |

|

|

Titanium / Carbon Steel / Titanium Clad |

Carbon steel plate and forging |

SA516 Gr.60(N),Gr.70(N),SA387 Gr.11, Gr.22, SA266, SA350, etc. |

(1.5~14)/(6~200)/(1~10) x W(max W 3000) x L(max L 6000) |

|

|

Titanium / Copper / Titanium Clad |

Copper, Naval Brass |

C10100, C10200, C11000, C26200, C28000, C46400, C70600, C71500, etc. |

(1.5~14)/(2~100) x W(max W 2100) x L(max L 6000) |

|

|

Titanium / Carbon Steel / Stainless Steel Clad |

Carbon steel plate and forging |

SA516 Gr.60(N),Gr.70(N),SA387 Gr.11, Gr.22, SA266, SA350, etc. |

(1.5~14)/(6~200)/(1.5~10) x W(max W 4110) x L(max L 7000) |

|

|

Duplex, Stainless Steel & their forgings |

304L,316L, 316Ti, 321, 317L, 310S, 410S, 904L, 1805, 2205, 2507, Al6XN, 254sMo,etc. |

|||

|

Zirconium / Titanium / Carbon Steel Clad |

Zirconium |

R60702 |

(1.5~14)/(1.5~2)/(2~200) x W(max W 4110) x L(max L 7000) |

|

|

Carbon steel plate and forging |

SA516 Gr.60(N),Gr.70(N),SA387 Gr.11, Gr.22, SA266, SA350, etc. |

|||

|

Aluminum / Titanium / Carbon Steel Clad |

Aluminum |

A1050, A1060, A1070, A1100, A5052, etc. |

(1.5~40)/(1-5)/(8~200) x W(max W 1000) x L(max L 1000) |

|

|

Carbon steel plate and forging |

SA516 Gr.60(N),Gr.70(N),SA387 Gr.11, Gr.22, SA266, SA350, etc. |

|||

|

Aluminum / Titanium / Copper Clad |

Aluminum |

A1050, A1060, A1070, A1100, A5052, etc. |

(1.5~40)/(1-5)/(1~100) x W(max W 1000) x L(max L 1000) |

|

|

Copper, Naval Brass |

C10100, C10200, C11000, C26200, C28000, C46400, C70600, C71500, etc. |

|||

|

Application: Petro-chemical, Vacuum Salt Industry, Chlor-alkali, Metallurgical, Food, Light Industry, Medicine, Auto Industry, Electrolytic Aluminum, Fertilizer, Kitchenware, Power Industry, Building Materials,Electrolysis Industry, Hydrometallurgy etc. |

||||

Competitive Advantage:

|

Competitive Advantage |

|

|

1. Abundant experience |

- More than one decade of abundant experience in non-ferrous metal cladding and production; - Miscellaneous metals cover Nickel Alloy, Titanium Alloy, Copper-Nickel Alloy, Zirconium, Tantalum Alloy, Super Stainless Steel; - Produced according to ASTM, ASME, JIS, DIN, ISO other codes; - Over 20 items of inventory or practical new-type patents. |

|

2. Professional technical consulting service |

- Generate technical specification to adopt in local market; - Technical bid evaluation and clarification; - Supplier technical document review, such as inspection and test plan, WPS / PQR, fabrication procedures, etc.; - Technical consulting on material, welding, NDE, etc.; - Non-conformance solution consulting; - Others that might be requested by customer. |

|

3. Independent inspection service |

- Technical clarification with customer; - Attend / organize pre-inspection meeting; - In-process inspection, including: Material inspection, Test witness, Visual & dimensional inspection, Welding inspection, NDE inspection, Coating inspection; - Final inspection on finished products; - Packing inspection; - Progress report and schedule expediting; - Other inspection might be requested by customer. |

|

4. Transportation advantage |

- 296kms away from Shanghai seaport |

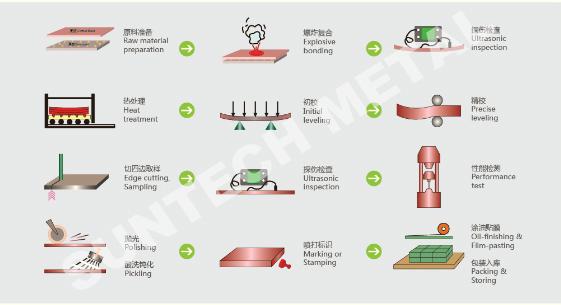

Production Procedure: